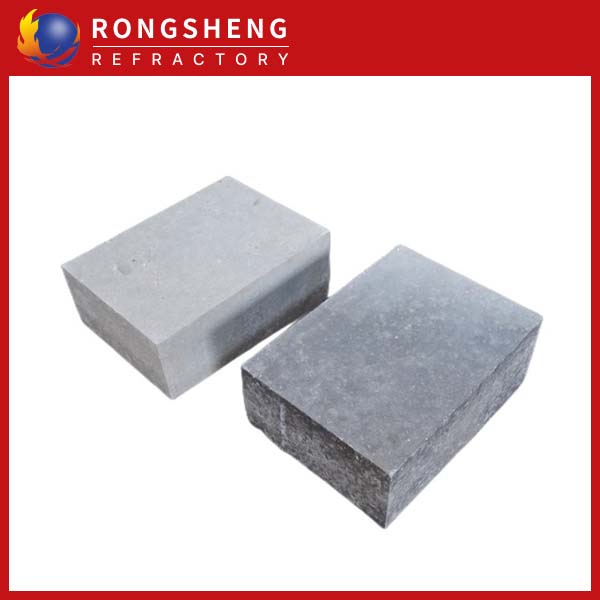

Phosphate-bonded high-alumina bricks are made of dense special-grade or first-grade high-alumina bauxite clinker as the main raw material, phosphoric acid solution or aluminum phosphate solution as a binder, and are semi-dry pressed and heat-treated at 400~600℃ to form chemically bonded refractory products. Phosphate-bonded high-alumina brick is unfired brick. In order to avoid large shrinkage of the products during high-temperature use, heating expansion raw materials such as kyanite, sillimanite, pyrophyllite, silica, etc., are generally required to be introduced into the ingredients. Compared with ceramic-bonded fired high-alumina bricks, they have better spalling resistance, but their load softening temperature is lower, and their corrosion resistance is poor. Therefore, a small amount of fused corundum, mullite, etc, need to be added to strengthen the matrix. Phosphate-bonded high-alumina bricks are suitable for cement kilns, electric furnace tops, ladles, etc.

Physicochemical indicators of phosphate bonded high alumina brick

| Item | RSP-75 | RSPA-75 | RSPT-1 |

| Al2O3 (%) ≥ | 75 | 75 | 80 |

| FeO2 (%) ≤ | 2.1 | 2.1 | 1.8 |

| Refractoriness (℃) | 1770 | 1770 | 1790 |

| Bulk Density (g/cm3) ≥ | 2.7 | 2.75 | 2.9 |

| Cold Crushing Strength (MPa) ≥ | 70 | 75 | 80 |

| 0.2MPaSoftening Temperature Load Degree T0.6 (℃) ≥ | 1350 | 1300 | 1520 |

| Thermal Shock Resistance(1100℃) Water Quenching (Cycle) ≥ | 20 | 20 | 15 |

Characteristics of phosphate bonded high alumina bricks

Alumina bauxite uses high-quality raw materials combined with aluminum dihydrogen phosphate and is finally dried in a drying furnace. It has high refractoriness, good wear resistance, high strength, and good thermal shock resistance, so it is very suitable for cement kiln transition zone and cooling zone lining materials. With high load refractoriness temperature, precise size, and stable performance, this brick has a short construction period and is energy-saving.

Application of phosphate bonded high alumina refractory bricks

- Inorganic non-metallic materials industry: cement kiln, glass kiln, ceramic kiln, etc.

- Metallurgical industry: steelmaking furnace, steel rolling heating furnace, soaking furnace, etc.

- Chemical industry: coal gasification furnace, coke oven, calcium carbide furnace, etc.

- Other industries include garbage incinerators, boilers, etc.

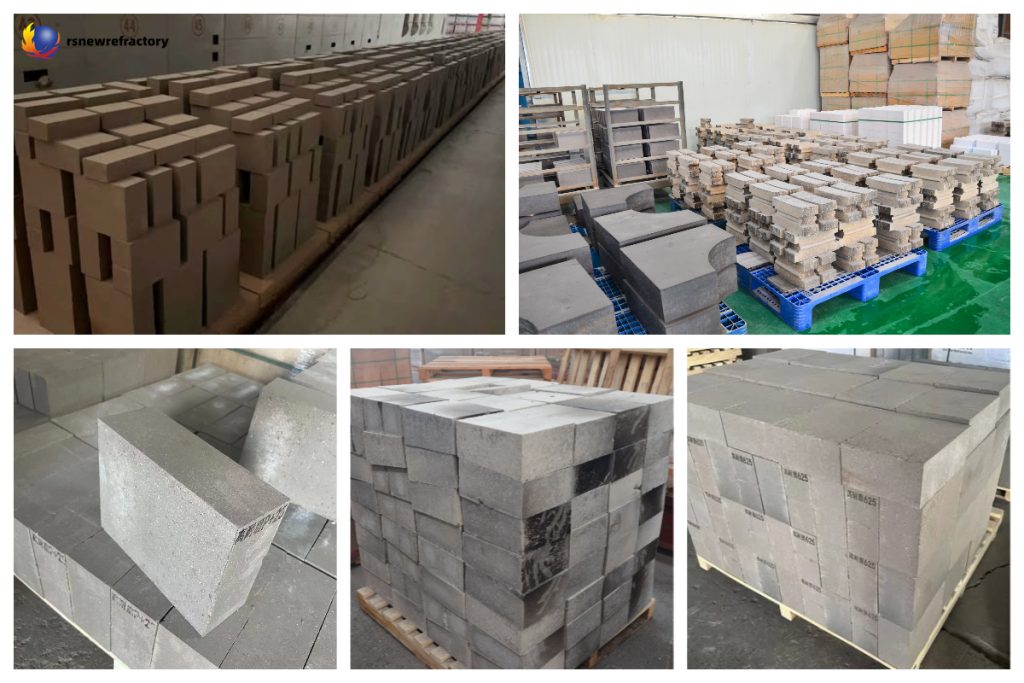

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat