Proceso de producción de ladrillo refractario de circón

Ladrillo refractario de circón( ladrillo de circón) es un material refractario de alto rendimiento que contiene un alto contenido de circón (Zarsio₄). Se usa ampliamente en campos de alta temperatura, como hornos de vidrio., metalurgia, metales no ferrosos, y productos químicos. Tiene las características de alta resistencia a la corrosión, buena estabilidad al choque térmico, y alta temperatura de ablandamiento de carga.

Introducción al proceso de fabricación de ladrillos de circón

El proceso de producción semiseco se puede utilizar para fabricar productos de circón unidos a arcilla. 2% Se agrega arcilla de plástico a la arena de circón y al polvo fino, y las propiedades del lodo se ajustan con electrolitos. El lodo se amasta y se moldea bajo una presión de 127MPa (moldear la humedad es 4%). El cuerpo verde se seca y se dispara a 1400 ℃. Al fabricar productos de circón puro, El polvo fino de circón se puede activar la superficie. La arena de circón y el polvo fino de circón con un tamaño de partícula de menos de 0.03 mm se mezclan en una proporción de 1:1, y se agrega líquido de desechos de pulpa de agua o sulfito para preparar el lodo, que esta amasado, moldeado (moldeo de humedad 4.5%), y disparado a 1450 ℃.

Proceso específico de producción de ladrillos de circón

Selección de materias primas: Las principales materias primas de los ladrillos de circón son el circón y otros materiales refractarios, como el óxido de circonio, alúmina, etc.. Estas materias primas deben ser cuidadosamente seleccionadas y proporcionadas para garantizar que los ladrillos tengan las propiedades refractarias requeridas.

Mezclar ingredientes: Las materias primas proyectadas se mezclan de manera uniforme según una determinada relación. Por lo general, una cierta proporción de aglutinantes y aditivos anti-cracking para mejorar la firmeza y la resistencia al calor de los ladrillos.

Moldeo y prensado: Las materias primas mixtas se colocan en un molde y se presionan en forma. Los ladrillos formados deben tener una determinada forma y tamaño para cumplir con los requisitos de sinterización y uso posteriores.

Tratamiento de sinterización: Los ladrillos formados deben ser sinterizados para darles excelentes propiedades refractarias en entornos de alta temperatura. Durante el proceso de sinterización, La temperatura y el tiempo deben controlarse para garantizar que la estructura y el rendimiento de los ladrillos mejoren bien.

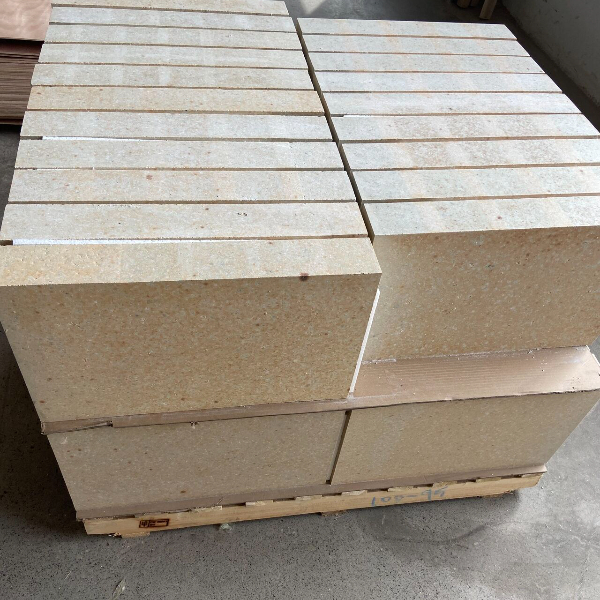

Inspección de calidad y embalaje: Los ladrillos de circón después de la sinterización deben ser inspeccionados para su calidad para verificar si su apariencia y rendimiento cumplen con los requisitos. Los productos calificados se empaquetarán en productos terminados para su uso en entornos de alta temperatura, como hornos.

Fábrica de refractarios de Rongsheng

Fábrica de refractarios de Rongsheng

WeChat

Escanea el código QR con wechat