Function of tabular alumina in Refractory Bricks

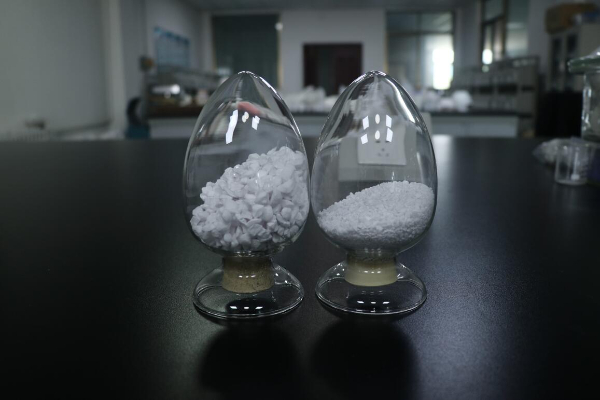

Tabular corundum is a large-grained sintered corundum made of high-purity alumina (Al₂O₃) xom ashyo sifatida, which is formed after high-temperature sintering (about 1900℃ or above). It is one of the most superior artificial sintered alumina materials. It plays a vital role in refractory bricks, which is mainly reflected in the following aspects.

The role of tabular alumina in refractory bricks

Improve refractoriness and stability

Tabular corundum has high refractoriness and melting point, and its Al2O3 content is usually above 99%, which enables refractory bricks to withstand higher temperatures without deformation or melting. Shuning uchun, tabular corundum can effectively improve the stability of refractory bricks in high temperature environments.

Enhanced thermal shock resistance

Tabular corundum has a unique crystal structure and excellent thermal stability, which enables it to significantly enhance the thermal shock resistance of refractory bricks. When experiencing rapid temperature changes, refractory bricks are less likely to crack or peel, thereby extending their service life.

Improve wear resistance

The tabular corundum has high hardness and wear resistance. Adding it to refractory bricks can significantly improve their wear resistance. This is especially important for occasions that need to withstand mechanical effects such as particle scouring and abrasion, and can ensure that refractory bricks maintain good performance after long-term use.

Optimizing physical properties

Tabular corundum has coarse crystals, a well-developed α-Al2O3 crystal structure, and good volume stability. These characteristics optimize the physical properties of refractory bricks, such as improving bending strength and thermal shock stability. Xuddi o'sha payt, tabular corundum has small pores and more closed pores, which makes refractory bricks have better thermal insulation and anti-permeability properties.

Expanding application areas

In industries such as steel, foundry, neft-kimyo, ceramics and incineration, high-performance refractory bricks can meet more stringent working environment requirements. Especially in the steel industry, tabular corundum refractory bricks cover almost the entire process of iron and steel making.

Rongsheng refrakter zavodi

Rongsheng refrakter zavodi

WeChat

QR kodini wechat orqali skanerlang