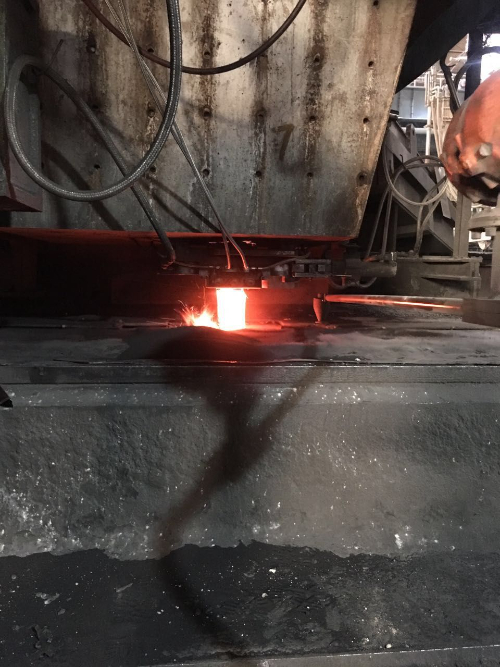

The tundish nozzle is a refractory component used in the continuous casting process of steelmaking. Located at the bottom of the tundish, it controls the flow of molten steel into the crystallizer. Ladle nozzles are typically made of materials such as alumina, zirconium oxide, and graphite, possessing properties of high temperature resistance and chemical corrosion resistance, and enabling precise regulation of the molten steel flow rate.

Tundish introduction

The tundish, located between the ladle and the crystallizer, primarily functions to regulate the molten steel flow rate, stabilize the molten steel temperature, and achieve purification and uniform distribution.

Tundish nozzle of physicochemical properties

| Chemical and Physical Properties | RSTN-AIC75 | RSTN-AIC80 | RSTN-AI75 | RSTN-Zr96RS | RSTN-Zr65 |

| Al2O3 ≥ % | 75 | 80 | 94 | -85 | – |

| ZrO2≥% | – | – | (Insert) 92-96 | 65 | |

| C≥% | 4 | 4 | – | – | – |

| Apparent porosity ≤ | 8 | 7 | 15 | 9 | 20 |

| Bulk density g/m3≥ | 2.90 | 2.95 | 2.95 | 3.05 | 3.5 |

| Compressive strength (ایم پی اے)≥ | 60 | 60 | 120 | 80 | – |

| High temperature bending strength (ایم پی اے) (1400*0.5h) ایم پی اے;z | 6 | 7 | 15 | 20 | – |

Zirconia insert–intergral material only zirocnia material.

| Chemical and Physical Properties | RSZR60 | RSZR70 | RSZR80 | RSZR85 | RSZR95 |

| ZrO2 ≥ % | 60 | 70 | 80 | 90 | 95 |

| Apparent porosity≤ | 21 | 20 | 18 | 15 | 6 |

| Bulk density g/m3 ≥ | 3.70 | 3.90 | 4.0 | 4.35 | 5.2 |

| Refractories≥℃ | 1800 | 1800 | 1850 | 1900 | 1900 |

Function of the ladle nozzle

- Steel Flow Guidance: Guides molten steel from the tundish to the crystallizer, ensuring a stable flow path.

- Flow Rate Regulation: Indirectly affects the molten steel flow rate by changing the nozzle diameter or shape (requires coordination with a stopper rod).

- Oxidation Prevention: Some nozzle designs (such as long nozzles) can isolate air, reducing secondary oxidation of the molten steel.

- Casting Protection: Submerged entry nozzles (SENs) prevent molten steel splashing and promote a stable molten steel surface within the crystallizer.

Features of the tundish nozzle

- Quick-change tundish sprue nozzles slide rapidly and precisely, without flow deviation or steel leakage.

- Excellent corrosion resistance, no significant diameter expansion, long service life, and no flow deviation or spillage.

- Good thermal shock resistance and excellent explosion resistance.

- Custom-made products can be quickly customized according to customer requirements.

Tundish sprue nozzles offer advantages such as heat insulation, reduced nozzle surface temperature, reduced heat loss, lighter weight, increased strength, and extended service life.

Tundish nozzle structure and material selection

The quick-change mechanism for tundish nozzles generally includes an upper guide plate, a left guide plate, and a right guide plate. The upper guide plate holds the tundish and the upper nozzle, which is located at the bottom center of the tundish. The left and right guide plates together support the lower nozzle. The material of the tundish nozzle is selected based on the steel grade being cast. For casting general carbon steel, mullite nozzles containing 70-75% Al2O3 can be used. For casting free-cutting steel, magnesium oxide or zirconium oxide nozzles can be used. For casting high-manganese steel, high-alumina graphite or zirconium oxide nozzles can be used.

Ladle Nozzle manufacture

Rongsheng Refractory Materials Co., Ltd. is an exporter of refractory materials, capable of supplying worldwide. Having cooperated with over 80 countries globally and possessing more than 12 years of production experience, its key products include refractory bricks, castables, موصلیت کا مواد, and ladle refractories. Rongsheng is a trustworthy partner.

رونگشینگ ریفریکٹریز فیکٹری

رونگشینگ ریفریکٹریز فیکٹری

WeChat

وی چیٹ کے ساتھ کیو آر کوڈ اسکین کریں۔