سلائیڈ گیٹ ریفریکٹری اینٹوں کی درجہ بندی

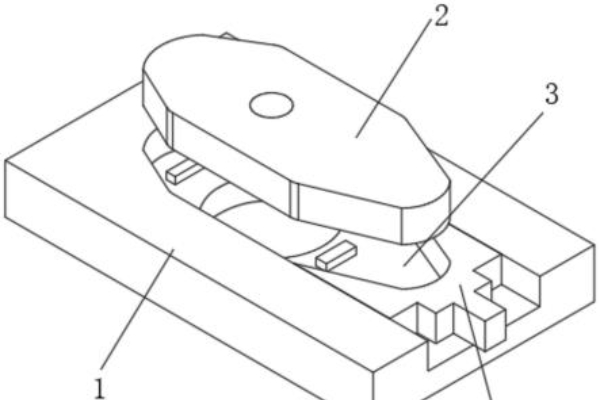

In the steelmaking and continuous casting process, the slide gate refractory brick is one of the key components for controlling the flow of molten steel, and bears the harsh environment of high temperature and mechanical impact. High-quality slide bricks can not only stabilize the flow of molten steel but also extend the service life of the overall refractory system and improve the quality of metallurgical products. This article will introduce the main performance and common classification of slide refractory bricks in detail to help you better understand and choose the right product.

سلائیڈ گیٹ ریفریکٹری اینٹوں کی درجہ بندی

In terms of manufacturing methods, slide gate refractory brick can be divided into fired bricks and unfired skateboard bricks. The materials of slide gate plates are mainly high alumina, corundum-mullite, magnesium, chromium, aluminum carbon, and aluminum zirconium carbon. اس وقت, the materials of the slide gate plate in China are mainly high alumina, magnesium, and aluminum carbon. Among the above materials, aluminum carbon skateboards have the longest service life, generally 3 to 5 furnaces.

Slide refractory bricks must have the following properties

- The sliding surface should be smooth, with a flatness of less than 0.1mm.

- The mechanical strength should be high.

- The corrosion resistance of molten steel and slag should be strong.

What are the main reasons for the damage to slide gate refractory bricks?

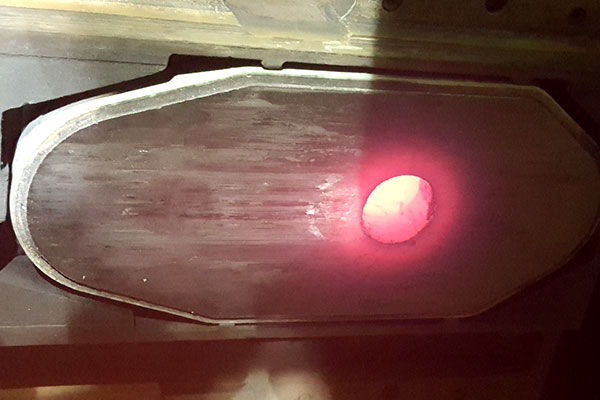

- The thermal shock of the steel flow causes the skateboard to crack and the sliding surface to peel off.

- The chemical erosion of molten steel and slag causes the skateboard aperture to expand and the sliding surface to melt.

- The repeated use of the skateboard causes the cracks to expand and the surface to be uneven.

- The uneven sliding surface causes the steel sticking.

رونگشینگ ریفریکٹریز فیکٹری

رونگشینگ ریفریکٹریز فیکٹری

WeChat

وی چیٹ کے ساتھ کیو آر کوڈ اسکین کریں۔