Proteja o aço fundido da oxidação quando ele fluir do distribuidor para o cristalizador, distribuir uniformemente o aço fundido no cristalizador, e controlar o estado de fluxo do aço fundido no cristalizador, com boa resistência à escória, antibloqueio, longa vida útil, e baixo índice de acidentes.

Indicadores físicos e químicos do bico submerso

Indicadores físicos e químicos:

| Item | Índice | |||

| JSK55 | JSK50 | JSK45 | JSK40 | |

| al2O3 % | ≥55 | ≥50 | ≥45 | ≥40 |

| C % | ≥16 | ≥18 | ≥20 | ≥22 |

| Resistência à flexão MPa | ≥5,5 | ≥5,5 | ≥5,5 | ≥5 |

| % de porosidade aparente | ≤19 | ≤19 | ≤19 | ≤19 |

| Densidade aparente g/cm3 | ≥2,36 | ≥2,32 | ≥2,28 | ≥2,18 |

Área de Escória:

| Item | Índice | |||

| Z75 | Z70 | Z65 | Z55 | |

| ZrO2 % | ≥75 | ≥70 | ≥65 | ≥55 |

| C % | ≥9 | ≥12 | ≥15 | ≥18 |

| Porosidade aparente % | ≤21 | ≤21 | ≤21 | ≤22 |

| Densidade aparente g/cm3 | ≥3,6 | ≥3,5 | ≥3,4 | ≥3,2 |

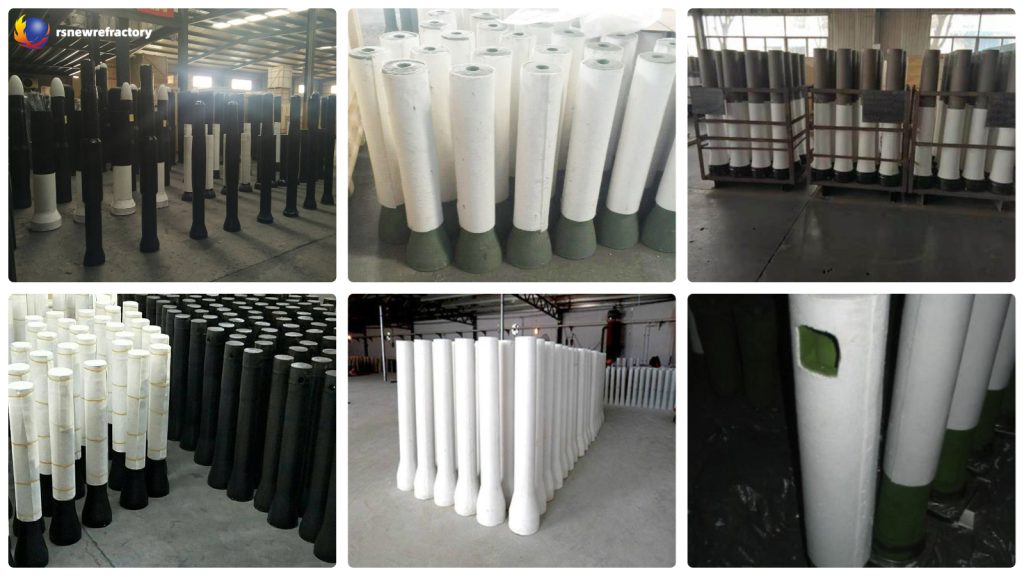

Introdução ao processo de produção do bocal de entrada submersa

O processo de produção de bicos submersos requer que várias matérias-primas sejam misturadas em um pó composto uniforme, que é então pressionado isostaticamente na forma desejada do corpo verde. Isto é então sinterizado em alta temperatura para formar um produto com uma certa resistência, que é então moldado e processado no tamanho necessário. Finalmente, após inspeção, é embalado e enviado.

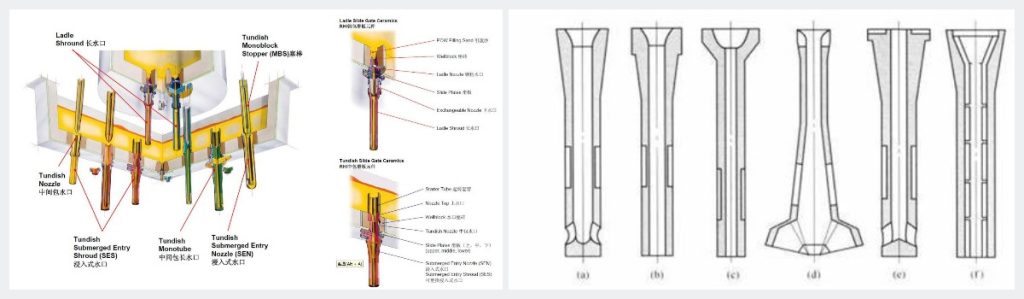

Tipo de estrutura dos bocais de entrada submersa (SEN)

Bicos de entrada submersos podem ser amplamente categorizados por sua aparência e estrutura interna, como mostrado na figura abaixo.

O Tipo A é um bico submerso com dois ou quatro orifícios laterais; O Tipo B é um bico submerso direto; O Tipo C é um bico submerso com boca hemisférica em forma de tigela, um bico combinado usado em conjunto com um bico distribuidor; O tipo D é de paredes finas, bico submerso de formato irregular, normalmente usado para lingotamento contínuo de placas finas; O tipo E tem uma face final plana, normalmente um bico de troca rápida; O tipo F tem um núcleo de zircônio embutido nele, usado para fundição contínua de tarugos.

Quais condições o bico submerso precisa atender?

1) Garanta a vazão do aço fundido na velocidade normal de tração.

(2) Faça a distribuição do fluxo de calor no molde e a seção transversal do lingote o mais uniforme possível;

(3) Facilitar o rápido derretimento da escória protetora;

(4) Facilitar a flutuação de inclusões sem rolar escória;

(5) Evite turbulência violenta do nível do líquido de aço no cristalizador;

(6) Fácil de instalar.

Seleção do material do bico imerso

Na fase inicial do lingotamento contínuo, o bocal de imersão de quartzo fundido com boa estabilidade térmica e alta pureza pode atender à fundição de aço carbono comum, aço com baixo teor de manganês, aço morto de alumínio e outros tipos de aço. No entanto, é severamente corroído sob condições de aço com alto teor de manganês e escória de alta alcalinidade. Neste momento, o bocal de imersão em alumínio e carbono é amplamente utilizado. As matérias-primas do bico de imersão em alumínio e carbono são bauxita de grau especial, corindo fundido ou corindo sinterizado, etc., com adição de grafite e antioxidantes. O produto tem as vantagens de resistência à corrosão e resistência ao choque térmico.

Apresentação da empresa Rongsheng

Rongsheng Company é um fornecedor profissional de materiais refratários, com mais de 12 anos de experiência em exportação, exportando para mais de 80 países. Os principais produtos da Rongsheng Company incluem vários tijolos refratários, materiais refratários não moldados, materiais metalúrgicos, materiais de isolamento térmico, e assim por diante.

Fábrica de Refratários Rongsheng

Fábrica de Refratários Rongsheng

WeChat

Escaneie o código QR com o wechat