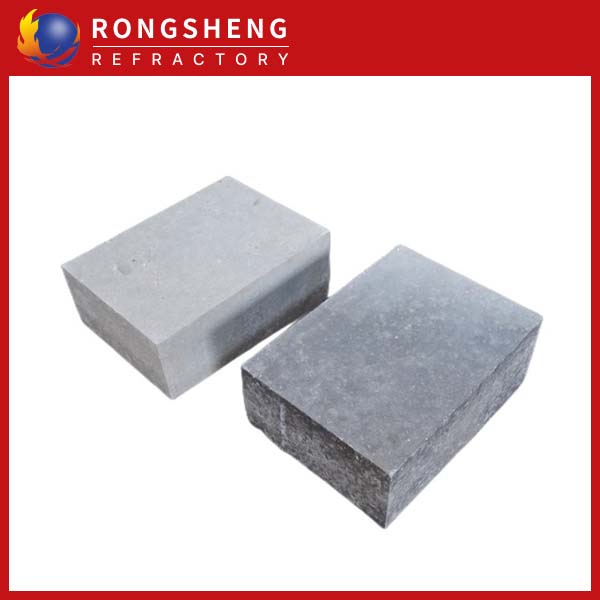

Phosphate-bonded high-alumina bricks are made of dense special-grade or first-grade high-alumina bauxite clinker as the main raw material, phosphoric acid solution or aluminum phosphate solution as a binder, and are semi-dry pressed and heat-treated at 400~600℃ to form chemically bonded refractory products. Phosphate-bonded high-alumina brick is unfired brick. In order to avoid large shrinkage of the products during high-temperature use, heating expansion raw materials such as kyanite, silimanita, pirofilita, sílica, etc., are generally required to be introduced into the ingredients. Compared with ceramic-bonded fired high-alumina bricks, they have better spalling resistance, but their load softening temperature is lower, and their corrosion resistance is poor. Portanto, a small amount of fused corundum, mulita, etc, need to be added to strengthen the matrix. Phosphate-bonded high-alumina bricks are suitable for cement kilns, Tops de forno elétrico, conchas, etc.

Physicochemical indicators of phosphate bonded high alumina brick

| Item | RSP-75 | RSPA-75 | RSPT-1 |

| Al2O3(%) ≥ | 75 | 75 | 80 |

| FeO2(%) ≤ | 2.1 | 2.1 | 1.8 |

| refratariedade(℃) | 1770 | 1770 | 1790 |

| Densidade aparente(g/cm3) ≥ | 2.7 | 2.75 | 2.9 |

| Força de esmagamento a frio(MPa) ≥ | 70 | 75 | 80 |

| 0.2MPaSoftening Temperature Load Degree T0.6 (℃) ≥ | 1350 | 1300 | 1520 |

| Resistência ao choque térmico(1100℃) Water Quenching (Ciclo) ≥ | 20 | 20 | 15 |

Characteristics of phosphate bonded high alumina bricks

Alumina bauxite uses high-quality raw materials combined with aluminum dihydrogen phosphate and is finally dried in a drying furnace. It has high refractoriness, good wear resistance, força elevada, e boa resistência ao choque térmico, so it is very suitable for cement kiln transition zone and cooling zone lining materials. With high load refractoriness temperature, tamanho preciso, e desempenho estável, this brick has a short construction period and is energy-saving.

Application of phosphate bonded high alumina refractory bricks

- Inorganic non-metallic materials industry: forno de cimento, forno de vidro, forno cerâmico, etc.

- Indústria metalúrgica: steelmaking furnace, steel rolling heating furnace, soaking furnace, etc.

- Indústria química: coal gasification furnace, coke oven, calcium carbide furnace, etc.

- Other industries include garbage incinerators, caldeiras, etc.

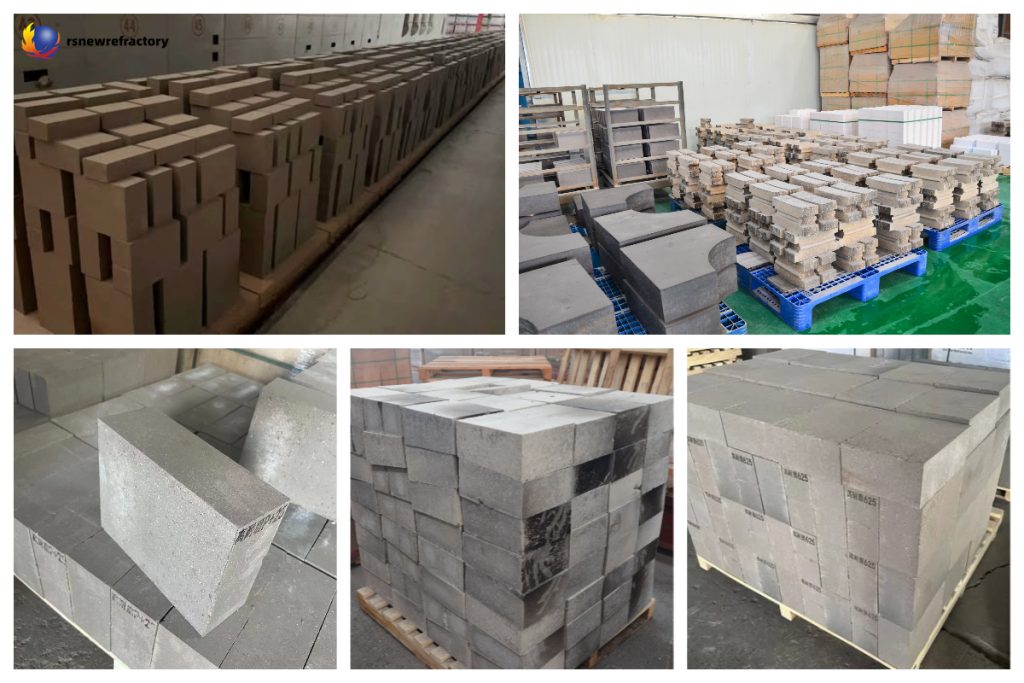

Fábrica de Refratários Rongsheng

Fábrica de Refratários Rongsheng

WeChat

Escaneie o código QR com o wechat