Introdução ao revestimento do forno vertical e seus materiais refratários

O forno de cal é um equipamento de alta temperatura usado para produzir cal viva (CaO). A cal é obtida pela calcinação do calcário (CaCO₃) e é amplamente utilizado na metalurgia, indústria química, materiais de construção, proteção ambiental e outras indústrias. Devido ao seu funcionamento contínuo, movimento do material de cima para baixo, e alta utilização de energia térmica, lime shaft furnace plays an important role in modern industry.

During the operation of the lime shaft furnace, the internal temperature can reach 900℃~1200℃, and the furnace lining is affected by high temperature, erosão química, mechanical wear, etc. for a long time. Portanto, choosing the right refractory material is crucial to extend the life of the furnace lining and improve production efficiency.

The structure of the lime shaft furnace

The straight lime shaft furnace is divided into three zones from top to bottom: zona de pré-aquecimento, calcining zone and cooling zone. According to the different functions of each zone, refractory materials of different materials and properties should be selected to obtain the best economic benefits.

Selection of refractory materials for the preheating zone of vertical furnace

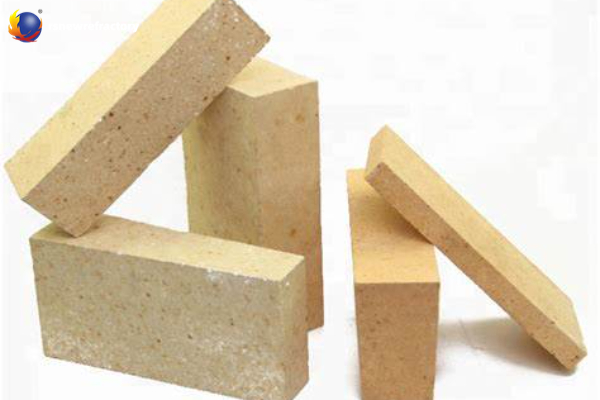

In the preheating zone, the furnace lining is mainly subjected to the impact and wear of limestone and the damage of high temperature caused by the upward movement of the calcining zone. The selection of refractory materials in this section mainly considers that the refractory bricks should have high bulk density and a certain load softening temperature and thermal shock stability. Geralmente, dense clay bricks with good wear resistance are selected.

Selection of refractory materials for the calcining belt

In the calcining zone, the furnace wall is mainly subjected to high temperature, wear of descending materials and scouring of ascending high-pressure airflow. Portanto, the selection of this section of the furnace lining should mainly consider the refractoriness and high load softening temperature. Além disso, since this section is the main decomposition area of CaC03, the chemical erosion caused by the contact of the selected refractory bricks with lime at high temperature and the embrittlement of the structure caused by the mechanical stress and thermal cracking of the lining bricks during operation require that the lining bricks of this zone should have strong resistance to chemical erosion and structural density. Portanto, neutral or alkaline dense refractory bricks are generally selected. Atualmente, the domestic main refractory bricks are high-density clay bricks, tijolos de alta alumina, tijolos de magnésia, tijolos de magnésia-cromo, and magnesia spinel bricks.

Fábrica de Refratários Rongsheng

Fábrica de Refratários Rongsheng

WeChat

Escaneie o código QR com o wechat