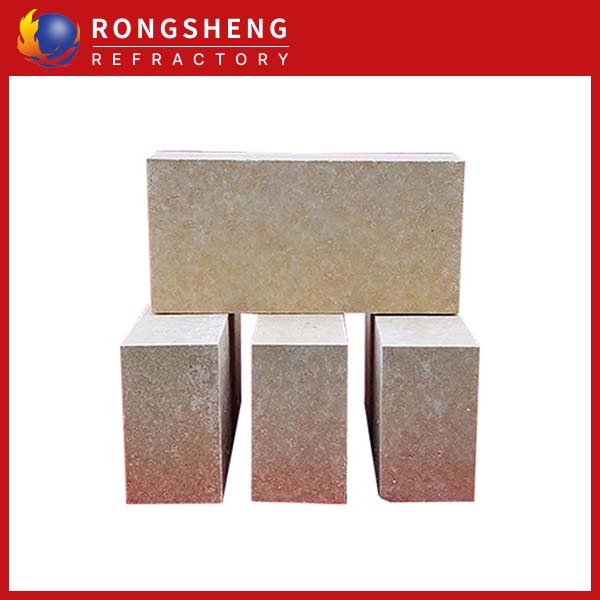

Sintered zirconia corundum bricks are sintered at high temperature by zirconia and corundum minerals.The glass liquid has the characteristics of strong erosiveness, high temperature resistance, Te pai o te ohorere o te mahanga, excellent high temperature creep resistance, strong corrosion resistance to slag and glass liquid, etc., and is used in glass furnace lattices, small furnaces, working pools, domes and forehearths and other parts.

Sintered zirconium corundum brick parameters

| Tūemi | Taurangi | ||

| AZS-16 | AZS-20 | AZS-32 | |

| ZrO2 % | ≥16 | ≥20 | ≥32 |

| Fe2O3 % | ≤0.4 | ≤0.3 | ≤0.3 |

| Bulk Density g/cm3 | ≥2.9 | ≥3.0 | ≥3.2 |

| Apparent Porosity % | ≤18 | ≤17 | ≤17 |

| Cold Crushing Strength MPa | ≥90 | ≥95 | ≥100 |

| 0.2Mpa Refractoriness Under Load ℃ | ≥1650 | ≥1700 | ≥1700 |

Characteristics of sintered zirconium corundum bricks

- Strong high temperature resistance It can maintain the stability of its physical and chemical properties at high temperatures, and can be used in high temperature environments above 1500 °C

2. Excellent corrosion resistance Sintered zirconium corundum bricks can withstand the corrosion of strong acid, strong alkali, oxidant and other chemical media, and have good corrosion resistance;

3. High strength and high hardness Sintered zirconium corundum bricks have high compressive strength and hardness, are not easy to break and damage, and have a long service life

4. Good thermal stability Sintered zirconia corundum bricks still maintain their shape and structure at high temperatures, and have good thermal stability

Sintered zirconia corundum brick application

- Metallurgical industry: used for lining of high temperature equipment such as furnaces, whakamate, and heating furnaces.

- Electric power industry: used for refractory materials inside the electric furnace, such as the hearth and furnace wall of the electric furnace.

- Chemical industry: used in high-temperature reactors, catalyst carriers, pipelines, valves, and other equipment.

- Other fields: It can also be used in glass melting furnaces, steelmaking, hanga sima, ceramic production, aerospace, me etahi atu mara.

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat