We are a leading refractory materials manufacturer and exporter, dedicated to providing high-performance solutions for all types of industrial furnaces and kilns. Whether you are building a new kiln or repairing an existing one, we offer durable, energy-efficient, and cost-effective refractory products to meet your needs.

Recommended refractory materials for different kilns

Cement rotary kiln

Cement rotary kiln is the main equipment for cement clinker calcination and the core part of a modern cement production line. It is a rotating cylinder structure with a certain inclination, which runs continuously at high temperature, pushing the raw materials from the feed end to the discharge end to complete the physical and chemical reaction process.

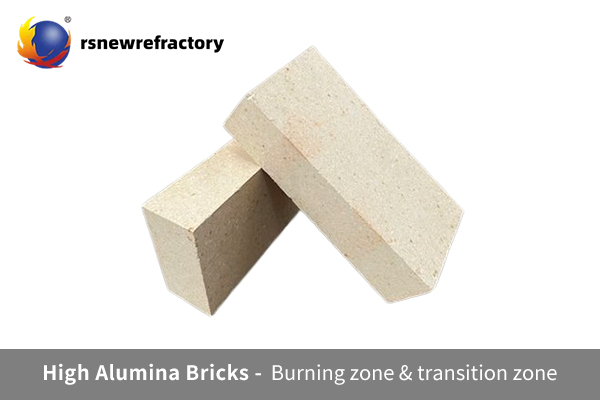

- High Alumina Bricks – Burning zone & transition zone

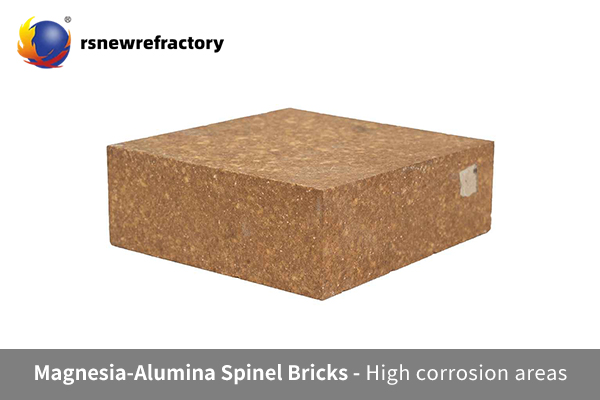

- Magnesia-Alumina Spinel Bricks – High corrosion areas

- Low Cement Castables – Preheater & cooler

- Ceramic Fiber Modules – Kiln hood insulation

Glass melting furnace

Glass melting furnace is a high-temperature industrial equipment used to melt raw materials (such as quartz sand, soda ash, calcaire, etc.) into glass liquid. It is one of the most critical core equipment in the glass manufacturing process. The internal temperature of the furnace is usually as high as 1350℃~1600℃, and it can run continuously for several years without interruption. The equipment structure and refractory materials are required to have extremely high resistance to high temperature and corrosion

- Silica Bricks – Crown and superstructure

- Fused Cast AZS Bricks – Glass contact areas

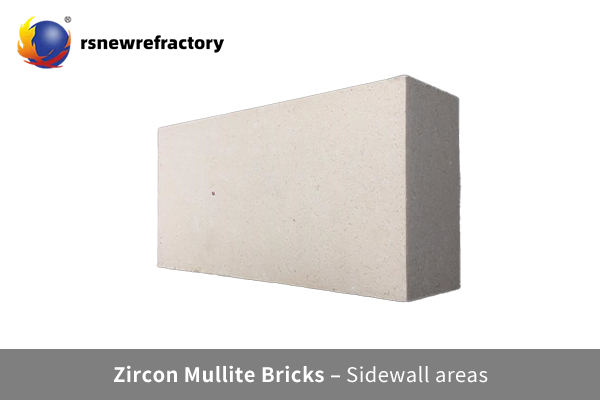

- Zircon Mullite Bricks – Sidewall areas

- Ceramic Fiber Blanket – Backup insulation

Steel Furnaces (EAF, LF, BOF)

Fournaise à arc électrique (EAF)

Les usages: Using scrap steel as the main raw material, a high-temperature arc is generated by electrodes to melt molten steel.

Caractéristiques:

Suitable for flexible, small batch, or alloy steel production

Can quickly heat up to above 1600℃

Commonly used in “short process” sidérurgie

Mainly uses refractory materials such as magnesia carbon bricks, briques à haute teneur en alumine, dry ramming materials, etc..

Ladle Furnace (LF)

Purpose: It is not used for melting, but as an auxiliary equipment for refining, heating, degassing and alloy adjustment of molten steel.

Caractéristiques:

It can control the composition and temperature of steel

It is often used for low-impurity and high-quality steel

The working environment is a high temperature, but the erosion is light

It usually uses aluminum-magnesium castables, anhydrous ramming materials, magnesium-calcium bricks, et autres matériaux

Basic Oxygen Furnace (BOF)

Les usages: Using molten iron as the main raw material, top-blown oxygen is used to oxidize impurities such as carbon to quickly complete the rough refining.

Caractéristiques:

High efficiency, large output, the main equipment of “long process” steel mills

Violent reaction, strong corrosion to the furnace lining

Refractory material requirements: Haute résistance à la corrosion, forte résistance aux chocs thermiques, commonly used magnesia carbon bricks, briques de magnésie chromée, etc..

Lime Kiln

Lime Kiln is a thermal equipment used to calcine limestone (Caco₃) to produce quicklime (CaO), which is widely used in steel, métallurgie, industrie chimique, matériaux de construction, fabrication du papier, environmental protection and other industries. Its core working principle is to heat limestone to 900℃~1200℃, decompose it into quicklime and release carbon dioxide gas.

- Magnesia Bricks – High refractoriness under load

- High Alumina Bricks – Preheating zone

- Mortier réfractaire & Castables – Repair and sealing

Incinerator

Incinerator is an industrial equipment used for high-temperature incineration of solid waste or hazardous waste, and is widely used in medical, urban garbage, chimique, métallurgique, énergie électrique et autres industries. Incinerators oxidize and decompose organic matter in waste through high-temperature combustion, and eventually convert it into harmless gas, ash or slag, parvenir à une réduction, harmlessness and resource processing.

- Corundum Castables – High wear & résistance aux alcalis

- Insulating Bricks – Heat retention

- Ceramic Fiber Modules – Secondary chamber lining

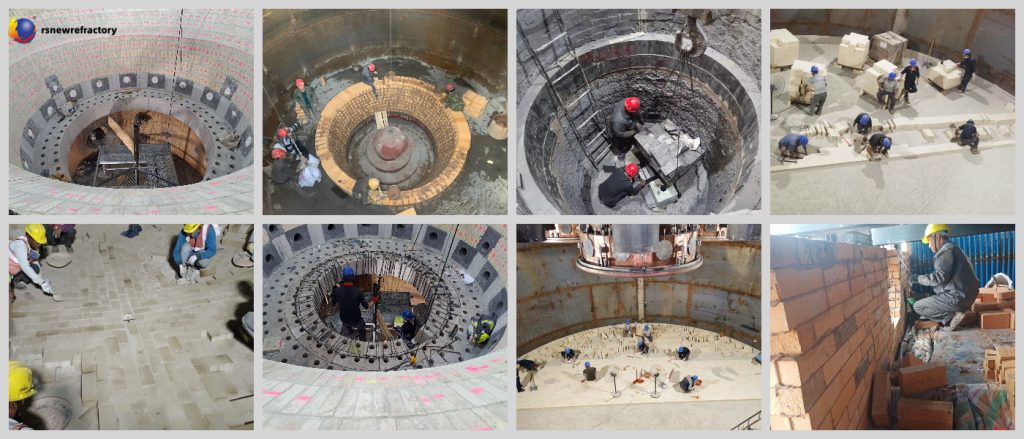

Kiln construction

Rongsheng has a professional construction team that can help with the construction and repair of kilns. Rongsheng a été créé pour 12 years and has professional technical engineers who can provide guidance.

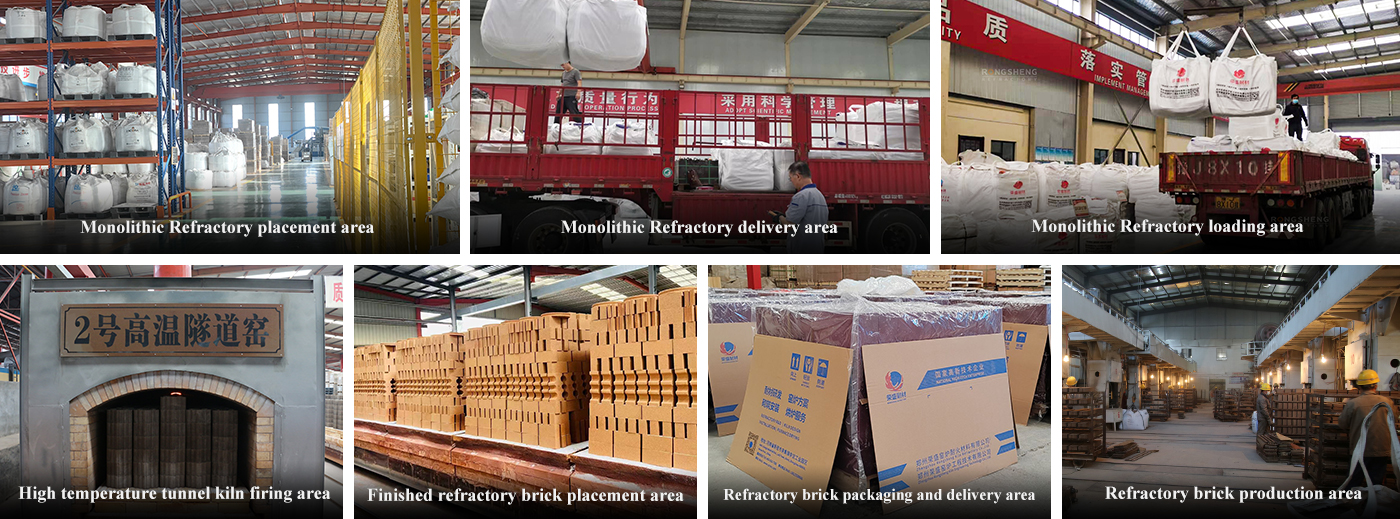

Usine de réfractaires de Rongsheng

Usine de réfractaires de Rongsheng

WeChat

Scannez le code QR avec wechat