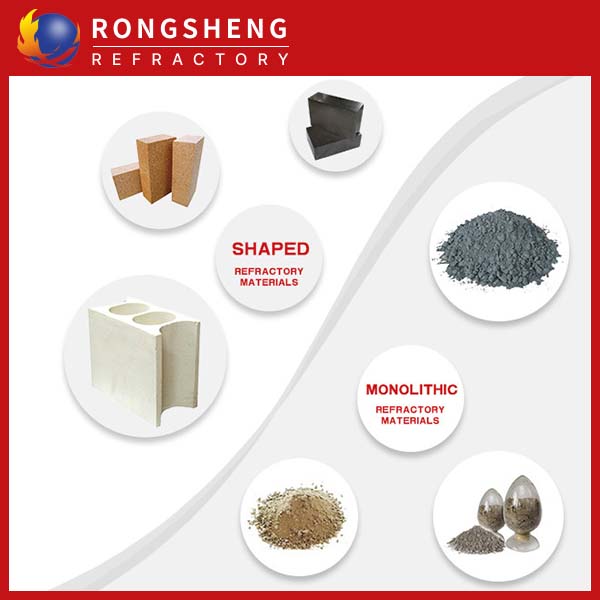

Welcome to Rongsheng Refractories! As a global leading supplier of refractory material manufacturers, we are committed to providing high-quality refractory products and professional refractory technical services to all walks of life. We can provide the most suitable refractory solutions for steel, salamin, ceramics, semento, petrochemical, power, or other high-temperature industries.

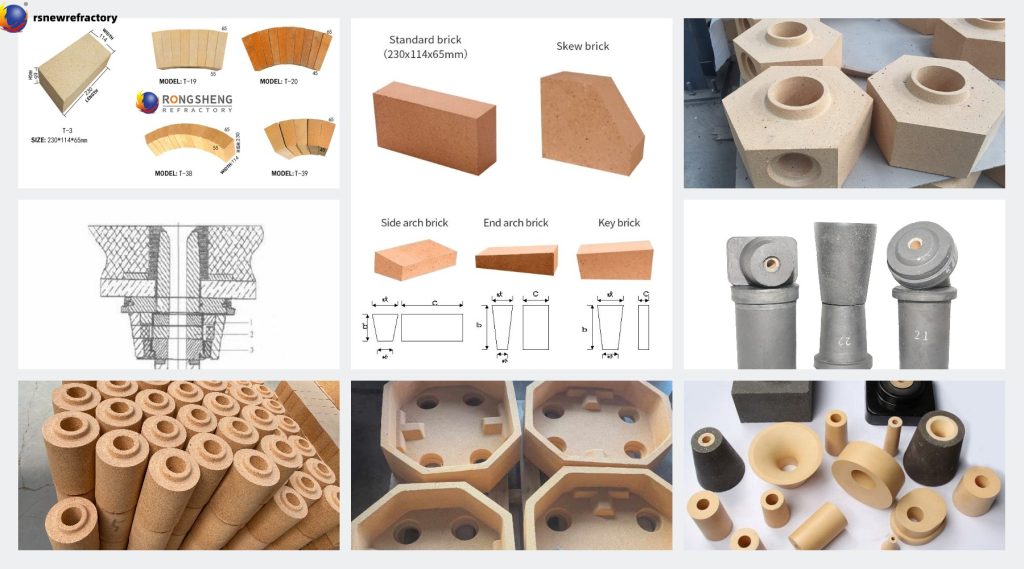

Refractory products for you to choose

High-temperature refractory bricks

We have hundreds of different refractory bricks for you to choose from. We can also recommend suitable high-temperature refractory bricks based on your kiln temperature and operating environment. The following are several popular refractory bricks.

High refractory temperature

Good strength

Paglaban sa kaagnasan ng kemikal

Good thermal conductivity

Long service life

Wear-resistant

| High Alumina Refractory Brick Physical and Chemical Index: | ||||||

| Item | Properties | |||||

| RS-80 | RS-75 | RS-65 | RS-55 | RS-48 | ||

| Al2O3(%) | 80 | ≥75 | ≥65 | ≥55 | ≥48 | |

| Refractoriness(°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

| Bulk density(g / cm3) | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

| Softening temperature under load(°C ) | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

| Reheating Linear changes Rate (%) | 1500°CX2H | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 1450°CX2H | -0.4 | -0.4 | -0.4 | -0.4 | -0.4 | |

| Apparent porosity (%) | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

| Cold crushing strength (Mpa) | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

| Paglalapat | steel furnace, glass furnace, sodium silicate furnace, ceramic shuttle kiln, cement rotary kiln, blast furnace, electric furnace, blast furnace and reverberatory furnace. | |||||

Magnesia Carbon Brick

- Good high-temperature resistance.

- Strong slag resistance.

- Good thermal shock resistance.

- Low creep at high temperatures.

- Low thermal expansion rate, not easy to deform.

- Not easy to peel off.

| Magneisa Carbon Brick | ||||||

| Item/Index | MGC-10 | MGC-12 | MGC-15 | MGC-18 | MGC-20 | |

| Bulk Density (g/cm3) | 2.95 | 2.90 | 2.85 | 2.80 | 2.78 | |

| Maliwanag na porosity (%) | 3~5 | 3~5 | 3~5 | 3~5 | 3~5 | |

| Compressive Strength (kg/cm2) | 450 | 400 | 400 | 350 | 350 | |

| Expansion at 1000 °C | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | |

| Komposisyon ng Kemikal (%) | MgO | 86 | 84 | 80 | 76 | 74 |

| F.C. | 10 | 12 | 15 | 18 | 20 | |

| Paglalapat | Ladle | EAFLadle | BOFEAFLadle | BOFEAFLF | BOFEAF | |

AZS Brick

1. Paglaban sa mataas na temperatura, high strength, widely used in various kilns

2. Raw material with high purity and high aluminum content

3. Mababang thermal kondaktibiti. Good thermal stability and corrosion resistance

4. The size is accurate and can be customized.

| Item | Fused Cast AZS Brick | |||

| Index | RS-AZS33 | RS-AZS36 | RS-AZS41 | |

| Chemical Composition% | Al2O3 | ≥50.00 | ≥49.00 | ≥45.00 |

| ZrO2 | ≥32.50 | ≥35.50 | ≥40.50 | |

| SiO2 | ≤15.00 | ≤13.50 | ≤12.50 | |

| Na2O+K2O | ≤1.30 | ≤1.35 | ≤1.30 | |

| Volume density g/cm3 | ≥3.75 | ≥3.85 | ≥4.00 | |

| Apparent Porosity % | ≤1.2 | ≤1.0 | ≤1.2 | |

| Cold Crushing Strength Mpa | ≥200 | ≥200 | ≥200 | |

| Exudation Temperature of Glass Phase | ≥1400 | ≥1400 | ≥1410 | |

| Bubble Separation Ratio(1300℃×10h) | ≤1.2 | ≤1.0 | ≤1.0 | |

| Anti-corrosion rate of glass liquid 1500℃×36h (mm/24h)% | ≤1.4 | ≤1.3 | ≤1.2 | |

| Bulk density(g/cm3) | Ordinary casting PT(RN RC N) | ≥3.55 | ≥3.55 | ≥3.70 |

| No shrinking casting ZWS(RR EVF EC ENC) | ≥3.65 | ≥3.75 | ≥3.85 | |

| Tilt casting QX(RO) | ≥3.65 | ≥3.75 | ≥3.90 | |

| No shrinkage casting WS( RT VF EPIC FVP DCL) | ≥3.75 | ≥3.80 | ≥3.95 | |

Silicon Carbide Mullite Bricks

Paglaban sa kaagnasan

Abrasion resistance

Thermal shock resistance

Good thermal conductivity

| Item | GM1650 | GM1600 | GM1550 | GM1680 |

| Al2O3 % | 63 | 60 | 57 | 63 |

| SiO2+SiC % | 30 | 30 | 30 | 30 |

| Apparent porosity % | 17 | 17 | 19 | 17 |

| Cold crushing strength Mpa | 85 | 90 | 90 | 100 |

| Refractoriness under load ℃ (0.2Mpa) | 1650 | 1600 | 1550 | 1680 |

| Thermal shock resistance(11oo℃, water cooling) | 10 | 10 | 12 | 13 |

| Bulk density g/cm3 | 2.65 | 2.60 | 2.55 | 2.65 |

| Cold abrasion resistance cm3 | 5 | 5 | 5 | 5 |

| Thermal conductivity(w/m·k) | 1.7 | 1.7 | 1.7 | 1.7 |

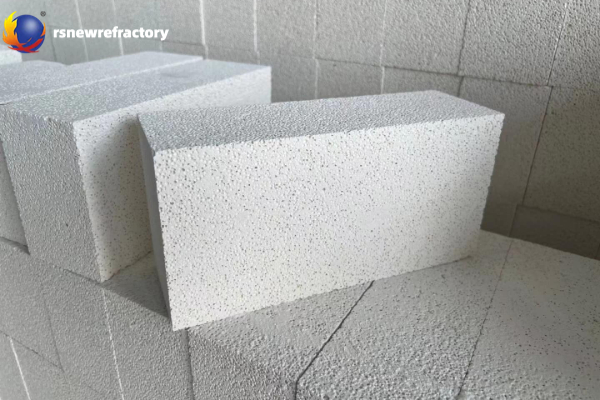

Insulation bricks

Mullite Insulation Brick

- Low heat fusion

- Mababang thermal kondaktibiti

- High refractoriness

- Good chemical stability

- High compressive and flexural strength

- Accurate appearance and size

| Mullite Insulation Brick | ||||||

| Item/Index | RS23 | RS26 | RS28 | RS30 | RS32 | |

| Al2O3 % | 37 | 54 | 64 | 72 | 77 | |

| Fe2O3 % | 1.0 | 0.9 | 0.8 | 0.7 | 0.5 | |

| Thermal Conductivity (w/m*k) | 400°C | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

| 600°C | 0.16 | 0.29 | 0.34 | 0.43 | 0.5 | |

| 800°C | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

| 1000°C | 0.20 | 0.33 | 0.38 | 0.45 | 0.53 | |

| Classification Temperature (°C) | 1260 | 1430 | 1540 | 1650 | 1760 | |

| Thermal Expansion 1000℃ (%) | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 | |

| Bulk Density (g/cm3) | 0.55-0.62 | 0.78-0.8 | 0.88 | 1.03 | 1.25 | |

| Malamig na Pagdurog ng Lakas (Mpa) | 1.2 | 1.6 | 2.1 | 2.5 | 3.5 | |

| Modulus of Rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

| Reheating Linear Change (%)CT-30℃*8H | 1230°C-0.5 | 1400°C-0.5 | 1510°C-0.5 | 1620°C-0.9 | 1730°C-0.9 | |

Monolithics refractory product

Monolithic refractory materials, also known as bulk refractory materials or amorphous refractory materials, refer to those refractory materials that are not formed by firing. Unlike traditional shaped refractory bricks, unstructured refractory materials do not have a fixed shape or size. They usually exist in the form of powder, granules, mud, or fibers. When used, they are directly poured, rammed, sprayed, applied, or filled at the construction site according to the needs.

Mga Castable na Mababa at Ultra Mababang Semento

- High refractoriness, high temperature, and low-temperature resistance

- Erosion resistance, impact resistance, high wear resistance, high strength

- Strong plasticity, can be cast into any shape

- Good air tightness, can reduce heat loss and save energy

| m | Ultra Low Cement Castable | |||

| Material | Clay | High Alumina | Corundum | |

| Bulk Density (g/cm3) | 2.35 | 2.70 | 3.20 | |

| Al2o3(%) | 45 | 75 | 95 | |

| Cao(%) | 1.15 | 1.15 | 1.15 | |

| Flexural Strength(Mpa) | 110℃*16h | 6 | 6 | 8 |

| 1500℃*3h | 8 | 8 | 10 | |

| Compressive Strength(Mpa) | 110℃*16h | 40 | 40 | 60 |

| 1500℃*3h | 70 | 800 | 90 | |

| Line change rate after burning(%) | 110℃*16h | -0.1 | 0 | 0 |

| 1500℃*3h | +-0.5 | +-0.5 | +-0.5 | |

| Refractoriness | °C | 1710 | 1790 | 1790 |

| Safe Service Temperature | °C | 1400 | 1450 | 1650 |

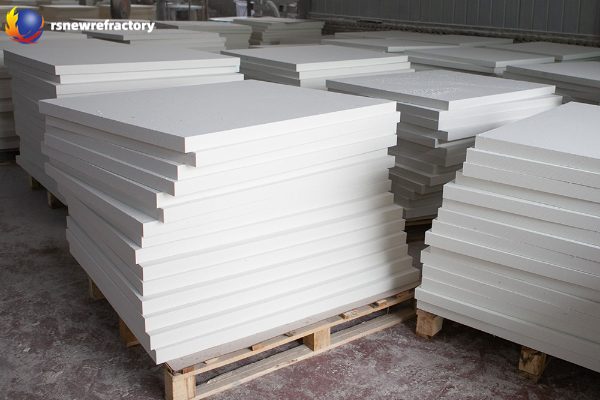

Ceramic fiber products

Customized other types of refractory products

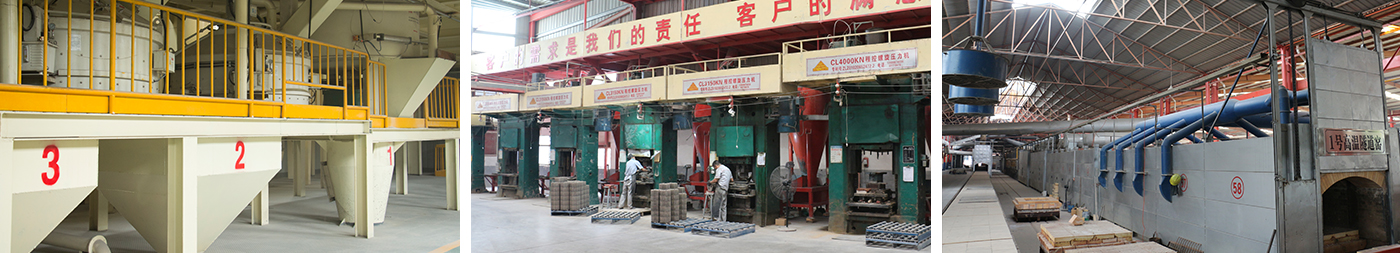

Refractory product production

Refractory material manufacturers’ customer cases

After 20 years of accumulation, we have many successful customers covering multiple industries and countries. For example, we provide high-alumina bricks for steel plants, customize high-temperature-resistant zircon bricks for glass plants, and provide various refractory products for foundries. Our products have been highly praised and trusted by customers.

Rongsheng Refractories Pabrika

Rongsheng Refractories Pabrika

Looking for stone bricks

4. X 9. X. 1 1/4

7807140474

Salamat sa iyong pagtatanong. Our sales team will contact you to discuss your project.