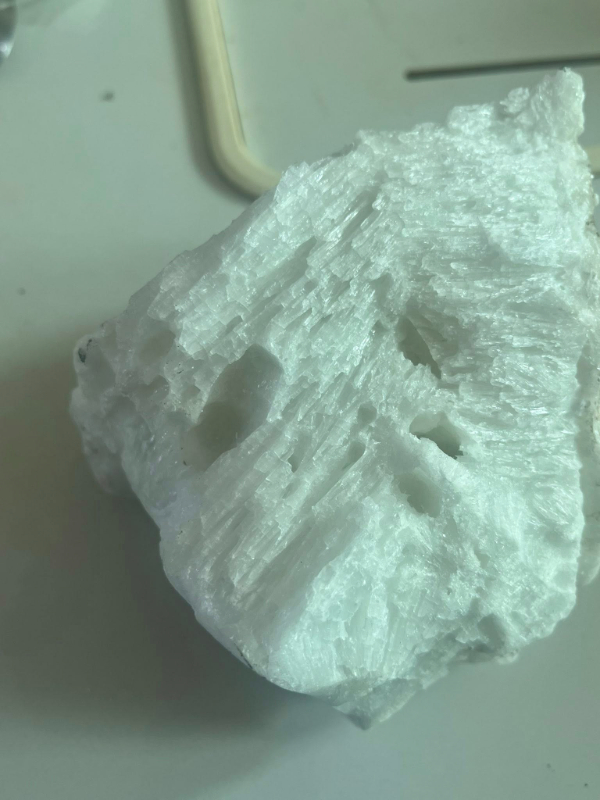

Fused mullite is a high-purity refractory material produced by melting high-purity quartz sand and industrial alumina in a certain proportion at high temperature in an electric arc furnace, and then cooling the mixture.

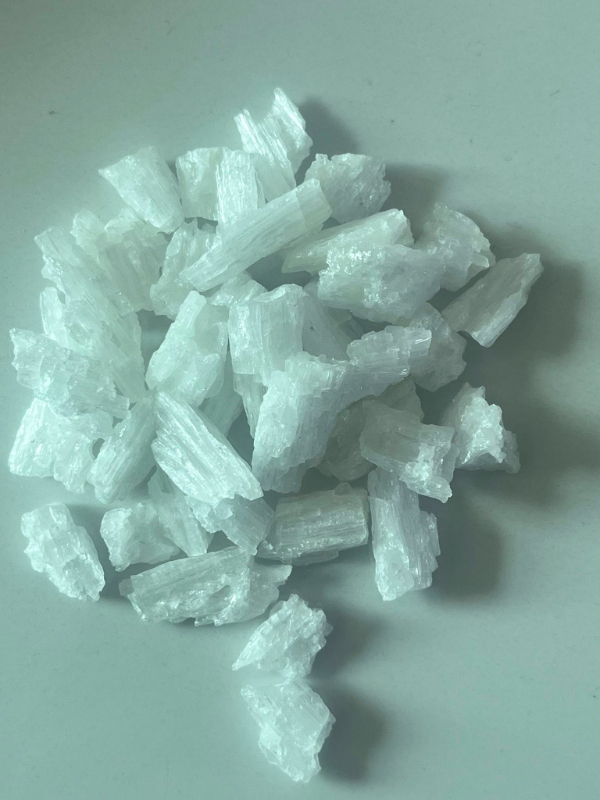

Fused mullite is characterized by well-developed needle-shaped crystals, high flexural strength, uniform expansion, good thermal shock stability, high load softening point, low creep at high temperatures, mataas na katigasan, and good chemical resistance. Fused mullite can be manufactured into various types of sand and fine powder according to customer requirements.

Applications of fused mullite

White fused mullite is widely used in various shaped products such as glass kiln lining bricks, large blast furnace hot blast stove bricks, ceramic kiln furniture, kiln shelves, saggers, continuous casting, three major components, mga brick ng corundum, water outlet valve seat bricks, and the petrochemical industry. It is a high-quality refractory material.

Fused mullite technical data

| Item | Unit | Data |

| AL₂O₃ | % | 72-77 |

| SiO₂ | % | 23-29 |

| Fe₂O₃ | % | ≤0.10 |

| R₂O | % | ≤0.50 |

| RO | % | ≤0.30 |

| Mullite Phase Content | % | ≥95 |

| Glass Phase Content | % | ≤5 |

| True Density | g/cm³ | ≥3.2 |

| Refractoriness | °C | ≥1840 |

| Grain Size | mm | 0-1,1-3,3-5 |

| Powder Size | mesh | -200,-325 |

Rongsheng Refractories Pabrika

Rongsheng Refractories Pabrika

WeChat

Scan ang QR Code sa wechat