متطلبات استخدام الألومنيوم من الطوب الكربوني في المغني

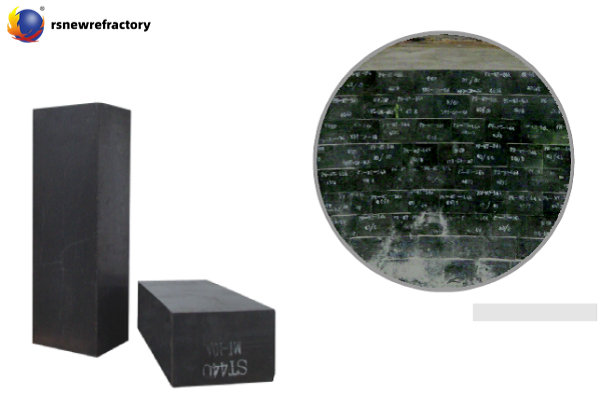

Rongsheng Refractory Company can provide aluminum-silicon refractory materials, magnesia refractory materials, ceramic insulation products and other high-temperature resistant materials. This article mainly introduces the requirements for the use of aluminum magnesia carbon brick in the ladle.

Ladle construction process

Pouring of permanent layer of the wall → Pouring of permanent layer of the bottom → Placing of nozzle seat bricks → Laying of air bricks and aluminum-magnesium-carbon bricks on the bottom → Filling of gaps with corundum binder → Laying of aluminum-magnesium-carbon bricks on the wall → Laying of magnesium-carbon bricks at the slag line of the wall → Laying of aluminum-magnesium castables on the mouth → Curing → Baking.

Construction of aluminum magnesia carbon brick for wall laying

Aluminum-magnesium fireclay is used for wet masonry. The masonry slurry should not be too thin. The slurry between brick joints should be full, and the brick joints should be less than 1mm.

Each layer of bricks should be laid flat, and the brick joints between layers must be staggered. During masonry, the principle of “solid back, tight joints, and arc closing” should be followed, and the joints between the upper and lower layers should be staggered.

The size of the cut door bricks should not be less than 50mm, and the door closing position should avoid the ear axis position. The door closing positions between layers should be staggered by more than 200mm.

Bottom-wrapped masonry construction technology

- The air bricks and nozzle seat bricks must be placed flat and in the correct position.

- After the nozzle seat bricks and air bricks are in place, the gaps between the surrounding bottom bricks should be filled with corundum binder.

Requirements for pouring construction

- Check the construction equipment (خلاط, water supply, vibrator, إلخ.);

- Turn on the mixer, add the mixture, dry mix for 1 minute, then add 2/3 of the water, then slowly add the remaining water, wet mix for 3 ل 5 minutes and discharge.

- Vibrate with a vibrator after each pouring and rolling, and require the pouring material to be fully exhausted.

- The pouring construction must be kept continuous before and after, and the material stop time during the process shall not exceed 20 دقائق.

Requirements for bottom excavation and repair construction

- Remove the seat bricks and the surrounding binder and clean them up.

- Lift the new air-permeable bricks and seat bricks into place;

- Use corundum binder to fill the gaps between the air-permeable bricks, nozzle seat bricks, and the aluminum-magnesium-carbon bricks at the bottom of the package;

مصنع رونغ شنغ للحراريات

مصنع رونغ شنغ للحراريات

WeChat

امسح رمز الاستجابة السريعة باستخدام wechat