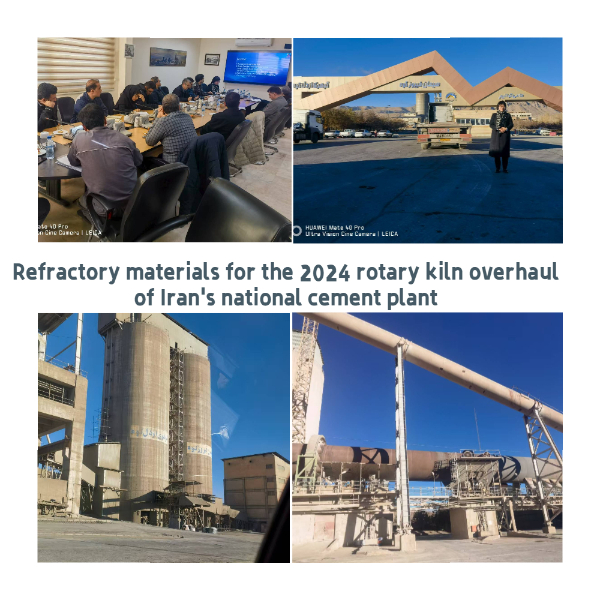

توفير مواد حرارية لإصلاح الفرن الدوار الإيراني

During a planned overhaul, a large cement plant in Iran urgently needed to completely replace the lining of its rotary kiln. Due to the kiln’s long-term exposure to high temperatures, high wear, and intense chemical corrosion, the existing lining had developed varying degrees of flaking and cracking, impacting production continuity and energy efficiency. To ensure a smooth overhaul, the client began searching for a reliable refractory supplier and discovered the website of Rongsheng Refractory Materials Co., المحدودة.

After contacting us, the customer gave us a detailed explanation of the operating conditions of their rotary kiln: the temperature in the kiln mouth area fluctuates greatly, requiring refractory bricks to have good thermal shock resistance; the firing zone has extremely high temperatures, requiring the material to have excellent resistance to high temperatures and slag erosion; and the transition zone and cooling zone need to have both strength and thermal insulation properties.

Customized complete refractory solutions

High-alumina bricks: Used in the kiln mouth and transition zone, they offer high refractoriness and thermal shock stability.

Refractory castables: Used in the firing zone and other areas subject to severe wear, they offer flexible construction, excellent integrity, and effectively extend the life of the lining.

الطوب العازل: Used around the kiln perimeter, they reduce heat loss and lower energy consumption.

Refractory material factory production

After confirming the plan, we immediately commenced production, strictly controlling the raw material ratio and process flow to ensure that the product performance met the requirements for high-temperature kiln operation. Furthermore, considering the customer’s tight overhaul schedule, we optimized the transportation plan to ensure all materials arrived safely in Iran within the stipulated timeframe.

Customer feedback about our refractory product

After the overhaul, the customer reported that the new lining operated stably and the refractory material performed exceptionally well, particularly under high-temperature shock and chemical attack conditions. This significantly extended the rotary kiln’s lifespan and reduced maintenance costs. The customer highly praised our service and product quality, expressing their willingness to pursue long-term cooperation.

مصنع رونغ شنغ للحراريات

مصنع رونغ شنغ للحراريات

WeChat

امسح رمز الاستجابة السريعة باستخدام wechat